Product

designs, supplies and supports advanced brushless motor and its drivers. We are working closely with OEM/ODM customers to bring rapidly to market, unique and innovative solutions.

-

EC flat motor

MKTL supplies full range brushless flat motors, EC Flat series, including φ45, φ60, φ90 diameter with different motor heights. The EC flat series have characteristics of compact structure, high torque, high dynamics, high efficiency, and low cogging torque, smooth operation. -

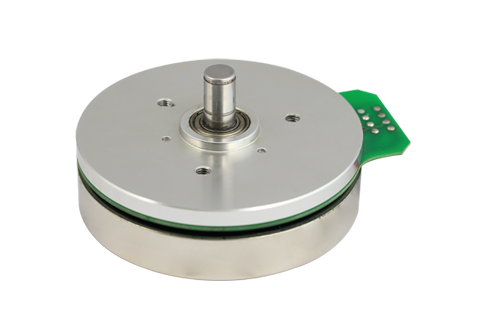

EC flat motor with encoder

The brushless DC motor (BLDC) combines high efficiency, compact design and precise control, suitable for a variety of automation and precision drive applications. The motor has a built-in high-resolution encoder to provide accurate speed and position feedback, ensuring the stability and reliability of system operation. -

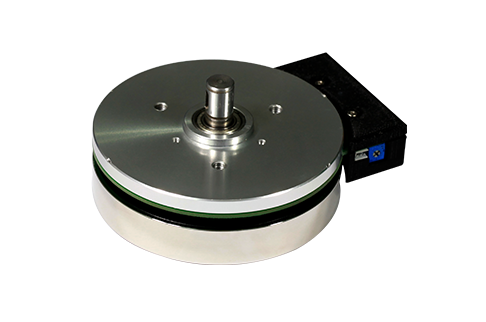

EC flat motor with encoder and integrated driver

1. The disc servo motor has the advantages of compact structure, high unit power density, small torque pulsation, and smooth operation. 2. The first built-in encoder technology, independent patent, has the advantages of anti-interference, anti-impact, and anti-pollution. It also adopts a built-in driver integrated structure, which is more compact and at the international leading level. -

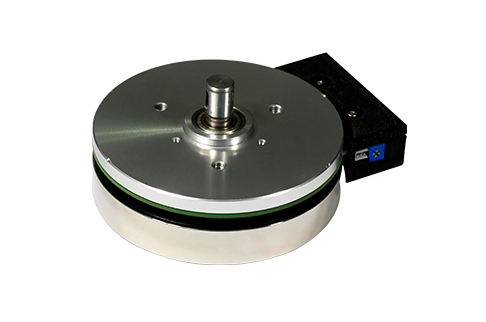

EC flat motor with integrated driver

The brushless DC disc motor (BLDC) with internal drive system is a compact and efficient motor solution with integrated drive. It integrates the brushless motor and drive control unit in the same housing, achieving plug-and-play, greatly reducing the wiring and control difficulty of external drives, and is widely used in industrial automation, robotics, medical equipment and other fields. -

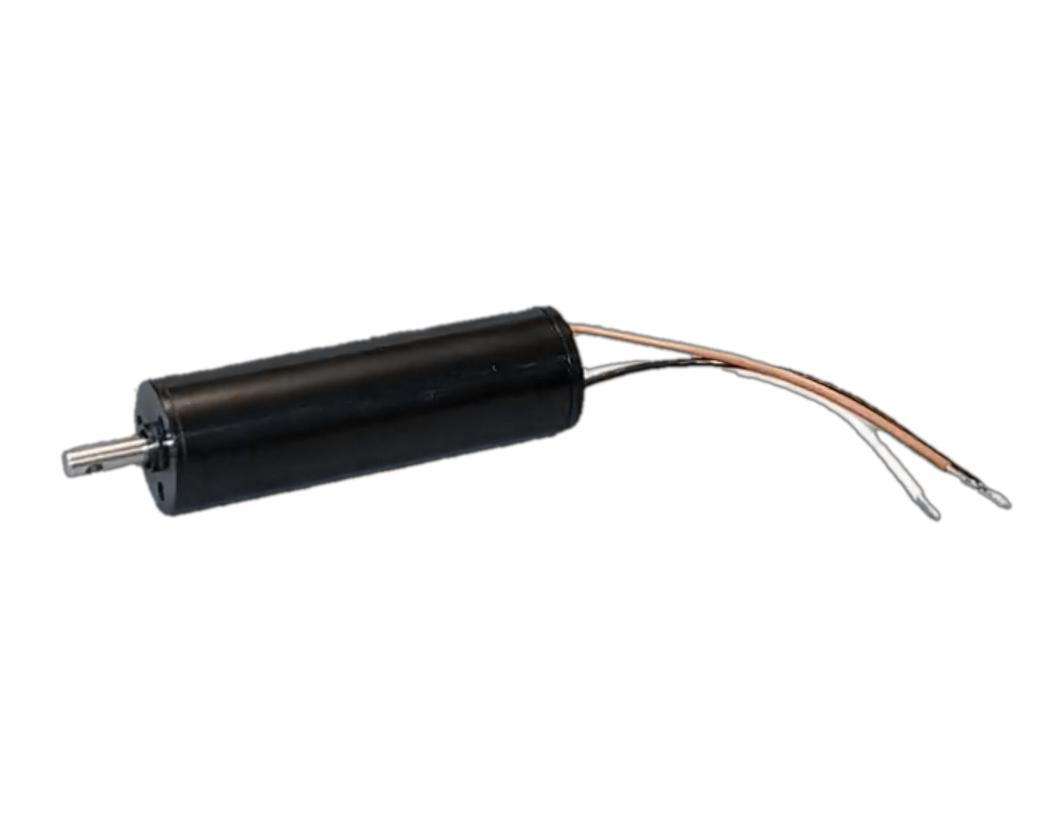

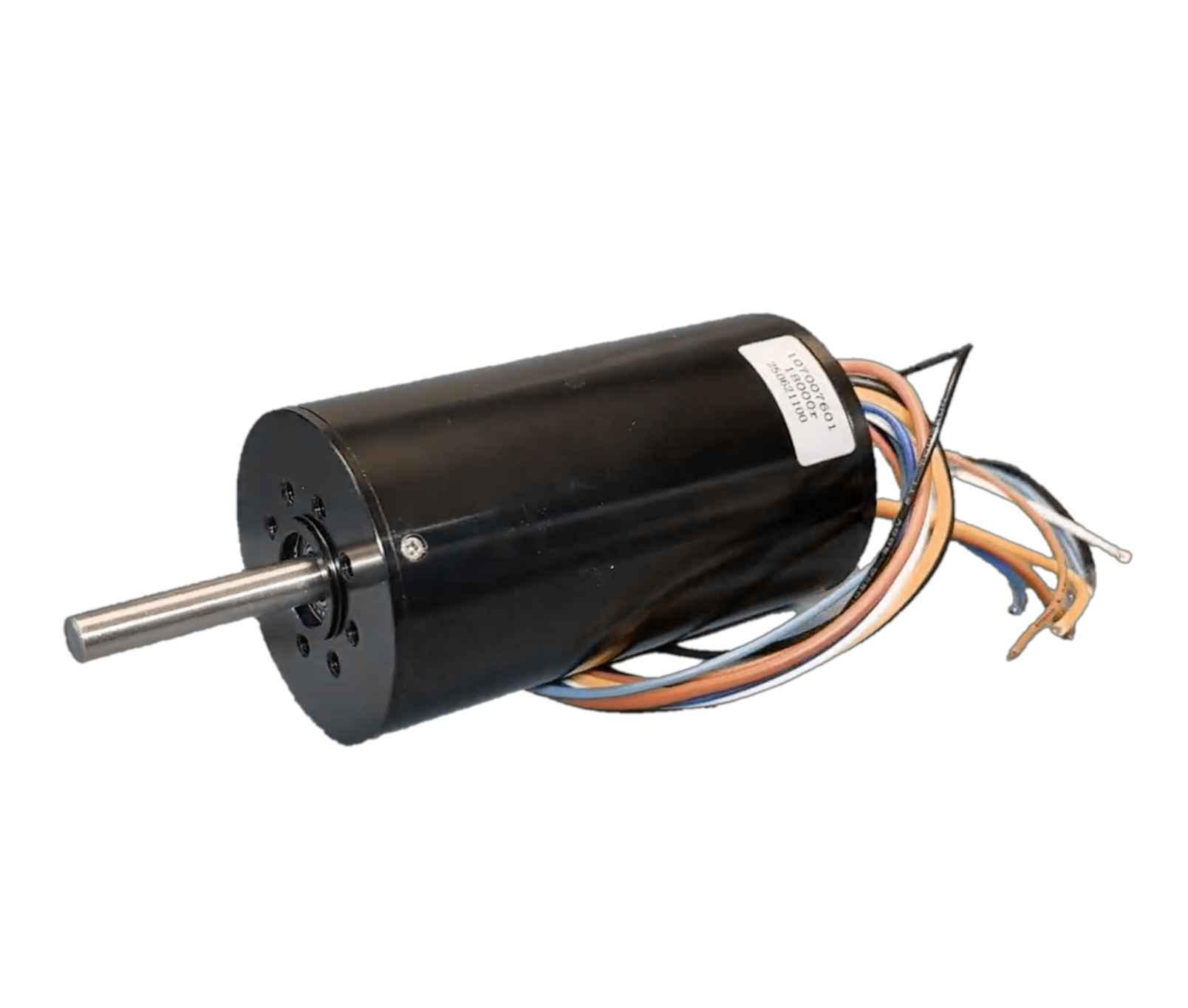

EC-max Series Overview

MKTL supplies full range brushless slotless motors, EC Max series, from φ10 to φ43, with different motor lengths. Our EC Max series uses NdFeB strong magnet and advanced winding technology to deliver high power in a compact size. The low inertia and short response time provide also high dynamics, which make EC Max series ideal for both-high speed operation and fast accurate positioning. -

EC-max | 14 series

Discover the MKTL EC Max 14 Series brushless motors with high-strength NdFeB magnets, low inertia, low noise, and high efficiency—perfect for robotics and precision automation applications. -

EC-max | 16 series

MKTL EC Max 16 Series brushless motors feature low-inertia, high-efficiency design with fast response—perfect for industrial automation, robotics, and aerospace devices. -

EC-max | 22 series

MKTL EC Max 22 Series brushless motors offer stable high-power output, low noise, and low vibration—ideal for medium-sized robots, drones, and automation equipment. -

EC-max | 28 series

Discover the EC-Max 28 series brushless DC motors: compact, high torque, and ideal for robotics, drones, and miniature automation. Precision and efficiency in a small footprint. -

EC-max | 30 series

The EC-Max 30 series delivers compact, reliable brushless DC motors for medical, industrial, and robotic applications. Smooth torque and easy integration for optimal performance. -

EC-max | 32 series

EC-Max 32 series brushless DC motors deliver high-speed, high-torque performance for UAVs, industrial automation, and precision tooling. Reliable and efficient for demanding applications. -

EC-max | 35 series

MKTL EC Max 35 Series brushless motors provide high torque and high efficiency with low inertia—ideal for high-speed precision robotics and industrial automation systems. -

EC-max | 43 series

MKTL EC Max 43 Series brushless motors deliver ultra-high power and torque with low inertia and high efficiency—perfect for large robotics, industrial automation, and precision equipment. -

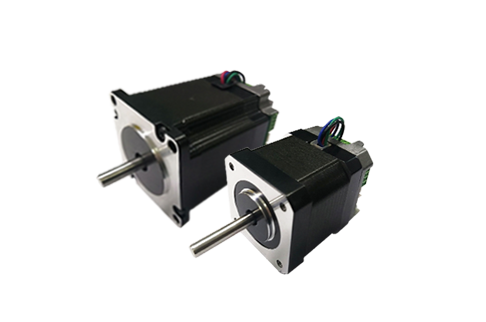

Stepping Motor

MKTL supplies full range stepper motors, with frame size range from 20mm to 85mm. Robust assembly, high torque, and exceptional performance in the harsh environments make MKTL’stepper motors the perfect solution for precision positioning applications. -

Stepping motor with encoder and integrated driver

Integrated Closed-loop stepper motor is a low-cost servo solution, which combines advantages of stepper motor and FOC servo control technology. Comparing to the open-loop stepper motor, it has the advantages of servo control, such as smooth operation with no loss step, no resonance, low noise, high efficiency and high acceleration etc. Comparing to servo motors, it has advantages such as stable low speed operation, high torque at low speed, short transient time, low cost and small size etc. -

Driver of servo motor

A wide range of powerful, compact drive electronics has been developed for all the motors we produce. These drives include independent external drives, as well as the integrated drives.